Compared with the soft pack and the square lithium battery, the 18650 cylindrical lithium battery is the earliest commercialized, one of the most automated and the lowest cost. There are also Tesla's many years of clamping, which basically keeps the situation with the soft pack and the square battery. Since Tesla announced that Model 3 has adopted 21700, the cylindrical battery family has also added a star member. This article takes a look at several technical points related to cylindrical batteries. Unless otherwise stated below, cylindrical batteries are specifically referred to as 18650.

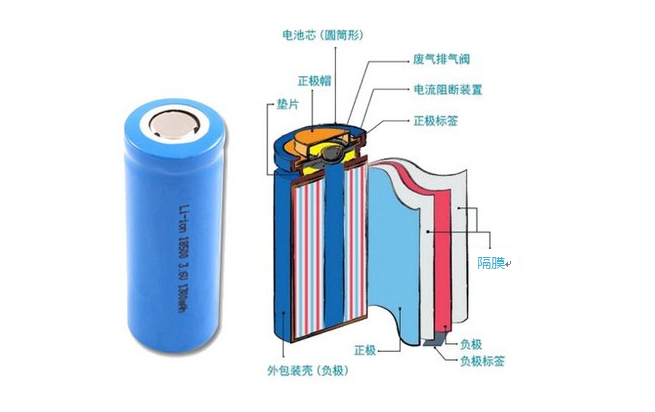

Cylindrical battery structure

Pay attention to the power battery and you will find that the cylindrical 18560 battery is the most studied battery type. The monomer is mainly composed of a positive electrode, a negative electrode, a separator, a positive electrode negative electrode collector, a safety valve, an overcurrent protection device, an insulating member and a casing. The shell has many steel shells in the early days, and is currently dominated by aluminum shells. The safety valve and PTC are shown in the figure below.

The single-current over-current protection device is not the same for each manufacturer. According to the different safety requirements, the price can be different and can be customized. The general safety devices mainly include PTC positive temperature coefficient resistors and fuse devices.

PTC, when there is too much current, the resistance heats up, the temperature accumulation promotes the rise of the PTC resistance value. When the temperature exceeds a threshold, it suddenly increases, which is equivalent to isolate the faulty cell from the overall circuit to avoid further thermal runaway. happened.

The fuse device, in principle, is a fuse that encounters a large current, the fuse is blown, and the circuit is broken.

The difference between the two protection devices is that the former can be recovered, and the latter protection is one-time. Once the failure occurs, the system must consider that the replacement battery is working properly.

Cylindrical core characteristics

Cylindrical batteries, especially 18650, due to their own structural characteristics, and due to the standardization of their models, the automation level of cylindrical battery production is the highest among the three main types of batteries. This makes high consistency possible and the yield is correspondingly improved. According to statistics, Samsung, Panasonic and other major foreign manufacturers can achieve 98% yield, while Chinese manufacturers can also exceed 90%.

Advantages, 1) as described above, the monomer uniformity is good;

2) The monomer itself has good mechanical properties, and the closed cylinder can obtain the highest bending strength under the approximate size compared with the square and soft pack batteries;

3) The technology is mature and the cost is low, but at the same time, the cost optimization space has already consumed almost the same;

4) The monomer energy is small, and the form is easy to control when an accident occurs, but this is also becoming the reason for its replacement (how to say the popular words, the one who will accomplish you will also destroy you, and the one who will kill you will also make You are strong, and things are the same.)

Disadvantages, 1) In the context of electric vehicles, the number of cylindrical cells in the battery system is large, which makes the battery system complexity increase, regardless of the mechanism or management system, system-level cost compared to the other two types of batteries. The cylindrical battery is high;

2) Under the condition of uneven temperature environment, the probability of alienation of a large number of cell characteristics increases. Of course, the reason why Tesla chose 18650 at the beginning of design is believed to be a helpless choice because it was capable of mass production 10 years ago. Qualified power battery, only cylindrical battery. The battery safety and thermal management needs, but the power of its powerful electronic control system.

3) The rising space of energy density is already very small. In 2016 news, Chaowei achieved a single capacity of 4050mAh and a cell specific energy of 306Wh/kg. Since then, no higher records have been seen. In the established space, only the dead material is recognized as a difficult road.

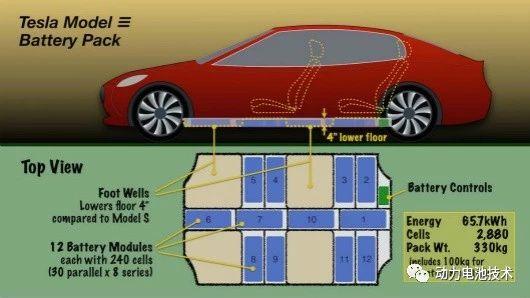

Tesila's Model 3 battery system with fire 21700

The Tesla Model 3 fully activates the 21700 ternary lithium battery, opening up a new phase of cylindrical battery boost capacity. Tesla Model 3's 21700 battery system has an energy density of 300Wh/kg. Compared with the original Model S, the 18650 battery energy density is increased by more than 20%, the monomer capacity is increased by 35%, and the system cost is reduced by about 9%.

21700 related manufacturers and models

At present, there are only a handful of companies capable of mass producing 21,700 batteries in the world. In addition to the 21700 battery production jointly developed by Panasonic and Tesla, Samsung SDI has also displayed related 21700 products. It is understood that the product has not been mass-produced.

Domestic 21,700 manufacturers, the news materials show that the manufacturers of the 21700 have BAK, Lishen, Yiwei Lithium, Tianpeng Power, Far East Foster, Lions New Energy and so on.

With the announcement of two products of Nanjing Jinlong and Beiqi, on August 16, the Ministry of Industry and Information Technology issued a new product announcement for the “Road Motor Vehicle Manufacturing Enterprise and Product Announcement” (No. 299). Among them, two pure electric vans (models NJL5040XXYBEV25 and BJ5040XXYCJ06EV) produced by Nanjing Jinlong Bus Manufacturing Co., Ltd. and Beiqi (Changzhou) Automobile Co., Ltd., were first equipped with 21,700 ternary lithium-ion batteries.

From 18650 to 21700, how do you think about the rise?

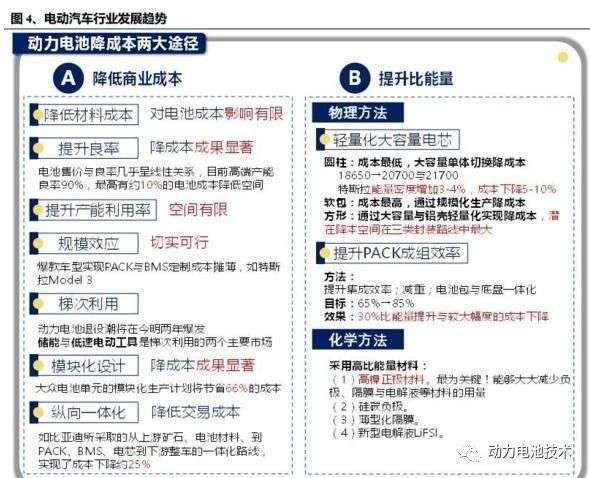

Since I saw this picture on the Internet, I always wanted to find a chance to put it in the article. There is no reason for it. The summary of the specific energy in the picture can be said to be comprehensive. Along the way in the figure, if the cell is more energy-efficient than the chemical method, the future of 18650 is not bright.

The challenges faced by the development of the 18650 lithium-ion battery, in the face of the current situation of people increasing the specific energy, if you maintain the same size and increase the energy density, the 18650 faces many challenges:

1) The supply of new materials such as NCA and silicon carbon is still immature, the cost is high, and the supply is difficult to stabilize. For example, the material 811 with higher energy density has a gap between its own stability and process control distance. The result is short-term. The 18650 inside the 811 is much more expensive, but the performance is quite poor;

2) The new material process has high environmental requirements, high fixed asset investment and huge energy consumption;

3) The capacity of the single battery is low, and the PACK group technical requirements and cost are high;

4) The single cell is adapted to the positive and negative bipolar structures at most, and the effect on energy density is significant;

5) When high energy density and high rate charging are required at the same time, the design space is very small. The 18650 uses 523+ graphite system. According to the new national standard, 1C has reached the limit of design.

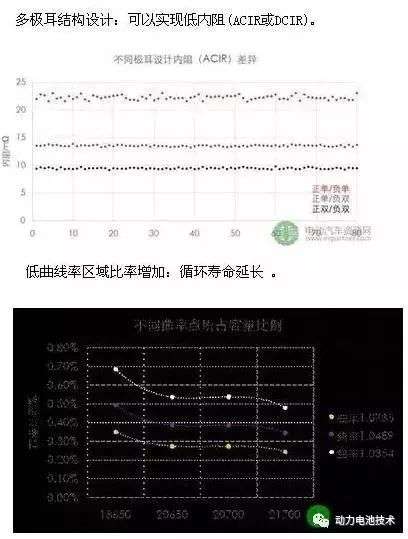

Larger-diameter cylindrical lithium-ion batteries will become an inevitable trend. The data is shown in the figure below. The larger-sized batteries are compared with the 18650 in terms of the ear design and the winding curvature. The large-size batteries show obvious advantages.

To sum up, the size has increased from 18,650 to 21,700, and the benefits are as follows:

1) Under the condition of appropriately increasing the energy density, conventional materials can be selected, and the performance is stable and cost-effective;

2) The multi-pole mechanism design can be properly performed to reduce the internal resistance;

3) Under the same energy density, fast charge characteristic graphite can be selected to improve fast charge performance;

4) More effective volume can be obtained by appropriately increasing the diameter and height.

5) The capacity of the single cell increases, the proportion of the auxiliary components decreases, and the cost of the package is reduced.

In the national standard "GB/T 34013-2017 electric vehicle power battery product specifications" issued by the Ministry of Industry and Information Technology, only 18650 and 32650 in the original consultation draft were revised into four specifications including 21700. A major benefit for the 21700.

However, the path to increase capacity conflicts with the early view that small monomers are equivalent to high security. The thermal safety of small lithium-ion batteries (<3Ah) and battery modules (<150Ah) has many mature methods to prevent and control, such as adding PTC, introducing current interruption mechanism or pressure sensor. The safety control issues of large lithium-ion single cells (>6Ah) or modules (>200Ah) still present challenges. Compared with small batteries, large-power lithium-ion batteries have higher energy content. When thermal safety problems occur, the consequences will be more serious. Due to the increase in battery volume, the specific surface area of the battery The reduction further reduces the heat dissipation area per unit volume of the battery. The inconsistency of the internal temperature of the battery also occurs with the enlargement and grouping of the lithium ion battery. The temperature difference between the battery cells causes an increase in the risk of thermal runaway of the battery, which causes a series of problems in the battery.

It is generally believed that if the manufacturer masters more advanced safety management technology, the risk can stay within the controllable range of its own system, and the risk caused by the battery unit can be hedged. Conversely, it can be said that the use of larger capacity batteries to build the system is theoretically based on the improvement of the single-design and battery pack design risk management technology.

The risks and benefits brought by the capacity increase are the obvious knowledge in the industry. Whether the OEM is fully accepted and willing to give it a certain security is a key part of the further development of the 21700. Personally, this requires a long time. The adjustments and updates to the equipment required to produce the 21700 are influenced by the equipment supplier's point of view.

Most of the advantages of cylindrical batteries come from their scale. Before the 21700 is really scaled up, there are also problems with the disposal of Class B products. This size that cannot be downgraded is also a test of the determination and financial strength of the manufacturers.

From the perspective of technology accumulation, the 18650 has been researched by enterprises and academic institutions for many years, and has a lot of public data and information, such as thermal management models, such as thermal runaway prediction. For small businesses whose R&D capabilities are still not perfect, it is also a resource. The 21700 is relatively blank.

For the development of the 21700 in the future, it is a lot of good, and the bad can also be listed. But this is a comparison inside the cylindrical battery. If you consider the competition between square batteries and soft pack batteries, the development of the 21700 may not come soon.

This article is organized by "power battery technology": lithium battery and fuel cell observation (formerly known as Asia Chemical Consulting - battery material), Xingye Electric, the first electric big cow said new energy maker, high-tech lithium battery, lithium power grid, lithium battery big data . The rest of the images are from publicly available sources on the Internet. Only for learning and communication, please indicate the source for forwarding.